- Home

-

Industries

-

Environment Testing

- Construction Dust Testing

- Drinking Water Testing

- Emerging Contaminants Testing

- Sea Water Testing

- Sludge Testing

- Soil Testing

- Solid Waste

- Stack Emissions Testing

- Stormwater Testing

- Subsurface Vapour Intrusion Assessment

- Surface Water Testing

- Wastewater Testing

- Watersheds and Rivers Testing

- Well Water Testing

- Asbestos Testing

- Mold Testing

-

Food Testing

- Beverage Testing

- Biscuit Testing

- Candy Testing

- Canned Food Testing

- Coffee Testing

- Condiments Testing

- Cooking Oil Testing

- Fast Food and Snack Testing

- Infant Food Testing

- Liquor Testing

- Meat and Meat Product Testing

- Milk & Dairy Testing

- Pet Food Testing

- Refrigerated and Frozen Food Testing

- Seafood Testing

- Tomato Products Testing

- Agricultural Products & Crops Testing

- Material Testing

- Chemical Products Testing

- Petroleum Products Testing

- Personal Care & Beauty Products Testing

- Household and Apparel Products Testing

- Healthcare Products Testing

- Building Products Testing

- Stationery and Office Supplies Testing

- Safety Testing of Nano Products

- Children Products Testing

-

Environment Testing

-

Services

- Agriculture & Crop Analytical Services

- Energy Analytical Services

- Environmental Analytical Services

- Food Analytical Services

- Material Characterization Services

-

Pharmaceutical Analytical Services

- Biopharmaceutical Characterization Services

- Deformulation (Reverse Engineering) Analysis Services

- Pharmaceutical and Medical Device Failure Analysis Services

- Pharmaceutical Impurity Testing Services

- Pharmaceutical Separation and Purification Services

- Preformulation Analysis Services

- Stability Analysis Services

- Compendial Testing

- Dissolution Testing

- Water Content Determination

- Pharmaceutical Water Testing

- Potency Testing

- Pharmaceutical Microbiology Testing

- Retail Products Analytical Services

- Textile Testing Services

- Karl Fischer (KF) Moisture Testing

-

Recommended Services

- Failure Analysis and Investigations

- Food Testing

- Pharmaceutical Testing

- Surfactant Testing

- Cosmetics and Skin Care Products Testing

- Karl Fischer (KF) Moisture Testing Service

- Textile Testing

- Microplastic Analysis and Testing

- Mold Testing Service

- Lubricating Oil Analysis and Testing

- Alloy Material Testing

- Deformulation Service

- Techniques

- AI SmartQC Platform

-

Resources

- Regulatory Resources

- Blog

- Application Notes

- Video Library

- White Paper

- Flyer

- Case Study

- Fee Schedule

-

Protocol

- Protocol for Deformulation of Pharmaceutical Products

- Experimental Procedure for Determining Trace Moisture in Food by Karl Fischer Method

- Experimental Procedure for Determining Moisture Content in Interior Wall Paint Using Karl Fischer Method

- Testing of Color Fastness to Rubbing for Textiles

- Qualitative Identification of Textile Fibers by Five Experimental Methods

- Tablet Dissolution Test - Determination of Dissolution Rate and Dissolution Rate of Azithromycin Dispersible Tablets

- Determination of Chemical Oxygen Demand (COD) in Water - Potassium Dichromate Method

- How to Detect Bacteria in Food: Total Bacterial Count Procedure

- Testing Coliforms in Food: MPN & Plate Count Methods

- Determination of Aflatoxin B1 in Food: ELISA & TLC Methods for Accurate Detection

- Determination of Molds and Yeasts in Food: Plate Count Methods for Accurate Detection

- Determination of Lubricating Oil Liquid Density - Density Meter Method

- Determination of Acid Value in Lubricating Oil - Potentiometric Titration Method

- ELISA Experimental Procedure for Detecting Aflatoxin B1 in Peanuts

- Careers

- About

- Contact

- Home

- Industries

- Stationery and Office Supplies Testing

- Paper Testing

Paper Testing

InquiryThrough our global network of testing experts and analytical equipment including chromatography (HPLC, GC, GC/MS) and atomic absorption spectroscopy (AAS, GFA, FIAS), Our goal is to provide test services as efficiently as possible to maximize our customers' profits. For more information about our services, contact one of our experts today.

Note: this service is for Research Use Only and Not intended for clinical use.

Whether it's daily writing, learning, printouts, posters, archives, black and white or color, we can't do without paper products. Alfa Chemistry's experts have a good understanding of paper products, including paper production processes, paper raw materials, and finished paper product testing and analysis. Alfa Chemistry can help companies, institutions and consumers around the world to conduct professional analysis and testing of the physical and chemical properties of office papers to ensure the quality and safety of products meeting the requirements of various guides.

Cultural paper and office paper that Alfa Chemistry can detect include but not limited to:

Carbonless Copy Paper

Writing Paper

Copy Paper

Envelope Paper

Watercolor Paper

Newsprint

Dictionary Paper

Calligraphy Paper

Book Paper

Drawing Paper

Our capabilities include but not limited to:

Alfa Chemistry's services ensure your products meet various requirements, such as:

ISO

ASTM

As a reliable third-party testing company, Alfa Chemistry provides Stationery and Office Supplies testing services to clients around the world to ensure the quality and safety of your products. With a professional analysis team and advanced instruments, we provide you with the most accurate testing results in the shortest time possible. To learn more about our services, please feel free to request a quote or consult our experienced scientists.

Techniques for paper testing

Physical Property Testing Instruments

- Bursting Strength Tester: Used to determine the bursting strength of paper, applicable for testing the bursting properties of corrugated cardboard, boxboard, and other materials.

- Thickness Gauge: Used to measure the thickness of paper, commonly including tools like vernier calipers and micrometers.

- Tensile Strength Tester: Used to measure the tensile strength and resistance of paper, suitable for various paper materials.

- Tearing Strength Tester: Used to measure the tearing properties of paper.

- Stiffness Tester: Used to measure the stiffness of paper, specifically its ability to recover after being subjected to force.

- Ring Crush Tester: Used to measure the ring crush strength of corrugated cardboard.

- Moisture Meter: Used to measure the moisture content of paper, suitable for corrugated base paper or cardboard.

- Brightness Tester: Used to measure the brightness of paper, suitable for evaluating the optical properties of paper.

Chemical Property Testing Instruments

- Fluorescent Whitening Agent Tester: Used to measure the content of fluorescent whitening agents in paper.

- Formaldehyde Tester: Used to measure the formaldehyde content in paper, suitable for environmental testing.

- Ink Absorbency Tester: Used to assess the ink absorbency of paper, suitable for printing paper and other specialty papers.

Appearance Quality Testing Instruments

- Gloss Meter: Used to measure the gloss of paper, suitable for evaluating the surface quality of paper.

- Dust Content Tester: Used to measure the dust content on the surface of paper.

- Smoothness Tester: Used to measure the surface smoothness of paper, suitable for printing and writing purposes.

Industry articles

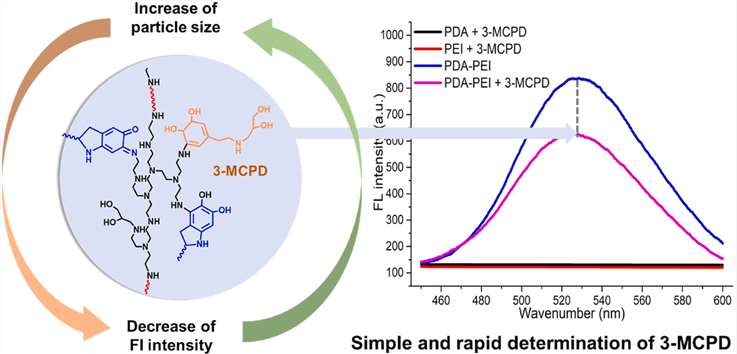

Fluorescence Detection of 3-MCPD in Food Contact Papers

Fang, Min, et al. Talanta 284 (2025): 127228.

Fang, Min, et al. Talanta 284 (2025): 127228.

This study developed a fluorescence method based on the copolymerization of polydopamine (PDA) and polyethyleneimine (PEI) for the determination of 3-monochloropropane-1,2-diol (3-MCPD) in food contact papers (FCMs). The copolymerization between dopamine and PEI, facilitated by Michael addition and Schiff-base reactions, results in a polymer with strong fluorescence at 527 nm. The presence of 3-MCPD enhances the fluorescence intensity, enabling its detection.

The method demonstrated a linear inverse relationship between fluorescence intensity and 3-MCPD concentration in the range of 10.0–500.0 μg kg−1, with a detection limit of 2 μg kg−1. The applicability of the method was confirmed in FCMs using the standard addition method, yielding recovery rates between 99.8% and 110.3%. A survey of 70 different FCMs revealed varying detection frequencies, with kitchen papers showing the highest levels of 3-MCPD contamination. More than half of the samples exceeded the limits recommended by the German Federal Institute for Risk Assessment.

This method provides an effective, sensitive tool for monitoring 3-MCPD levels in food contact papers, addressing concerns regarding the potential human exposure to harmful substances from FCMs.

Detection of Bisphenol A in Food Contact Papers Using Cd-MOF-Based Fluorescence Nanosensor

Rashdan, Huda RM, et al. Microchemical Journal 207 (2024): 112125.

Rashdan, Huda RM, et al. Microchemical Journal 207 (2024): 112125.

A cadmium-metal organic framework (Cd-MOF) was developed as a turn-off nanosensor for the sensitive detection of bisphenol A (BPA) in food contact papers (FCPs). BPA is a known endocrine disruptor with potential health risks, making its detection in FCPs essential for food safety. The Cd-MOF structure was characterized using field emission scanning electron microscopy (FESEM) and energy-dispersive X-ray (EDX) analysis, revealing a flake-like morphology and the presence of C, O, N, S, and Cd. A nonporous structure with a surface area of 25 cc/g was confirmed by BET analysis.

The Cd-MOF exhibited fluorescence emission at 470 nm upon excitation at 320 nm. Increasing BPA concentrations resulted in a measurable fluorescence quenching, allowing for quantitative detection. The method demonstrated a linear range of 0.05–1.0 µg/mL and a detection limit of 0.01 µg/mL, indicating high sensitivity. BPA extraction from FCPs involved methanol-based vortex mixing, ultrasonication, and centrifugation, followed by fluorescence analysis of the supernatant. The recovery rates were consistent, confirming the method's reliability.

The analytical performance was validated according to ICH guidelines and evaluated using the AGREE and ComplexGAPI indices, confirming its eco-friendliness and cost-effectiveness. The Cd-MOF-based method enables rapid and accurate BPA detection in food contact papers, reinforcing food safety and consumer health protection.

Characterization of Paper Quality Using FTIR-ATR and UV-Visible Spectroscopy

Pavithra, R., et al. Int. J. Curr. Res. Aca. Rev 3 (2015): 42-59.

Pavithra, R., et al. Int. J. Curr. Res. Aca. Rev 3 (2015): 42-59.

Paper is primarily composed of cellulose fibers derived from wood and non-wood materials, with various additives introduced to enhance quality during the papermaking process. The assessment of paper quality, particularly the influence of coatings and sizing agents on print quality, is critical for optimizing paper performance in printing applications. This study employed Fourier Transform Infrared Universal Attenuated Total Reflection (FTIR-UATR) and UV-Visible spectroscopy techniques to evaluate paper quality and coating efficiency.

FTIR-ATR in the mid-IR region was used to monitor the removal of lignin, extractives, and the incorporation of additives. The spectral responses provided precise fingerprints for identifying chemical modifications and additive interactions. UV-Visible spectroscopy was employed in both reflectance and transmittance modes to assess the optical properties of paper with similar density. The spectral variations were linked to coating and sizing efficiency, offering insights into the paper's printability and overall quality.

The combined spectroscopic methods demonstrated high reliability and sensitivity in detecting subtle differences in paper composition and performance. This analytical approach allows for improved quality control in paper manufacturing, enabling manufacturers to optimize the formulation of coatings and additives for enhanced print performance. The results underscore the importance of advanced spectroscopic techniques in ensuring consistent paper quality and improving end-user satisfaction in printing applications.

- Regulatory Resources

- Application Notes

- Blog

- Ordering Process

- Ask a Question

Do not know how to place an order, please refer to the flow chart shown below.

Submit quotation request |

A technical manager will contact you within 24 hours |

You will review and approve the final price and place an order |

Confirm with you and make the payment |

Instruct you to ship your samples and form |

Analytic report delivery |