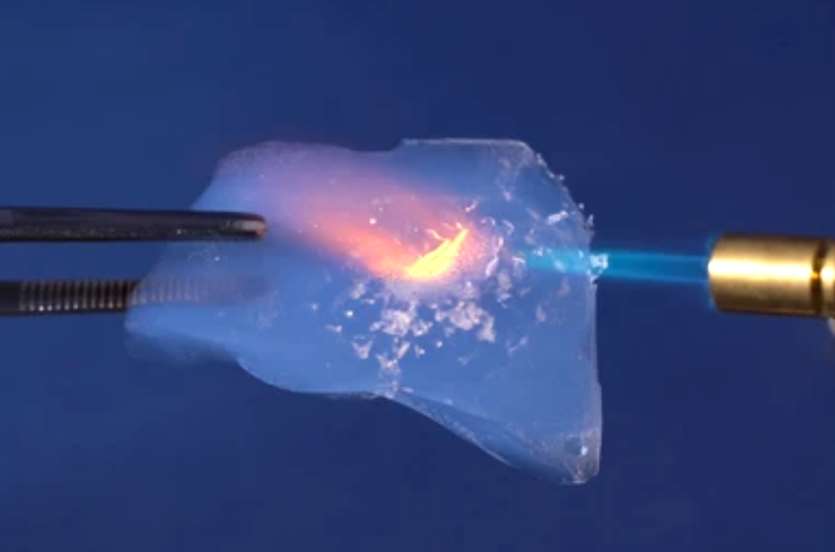

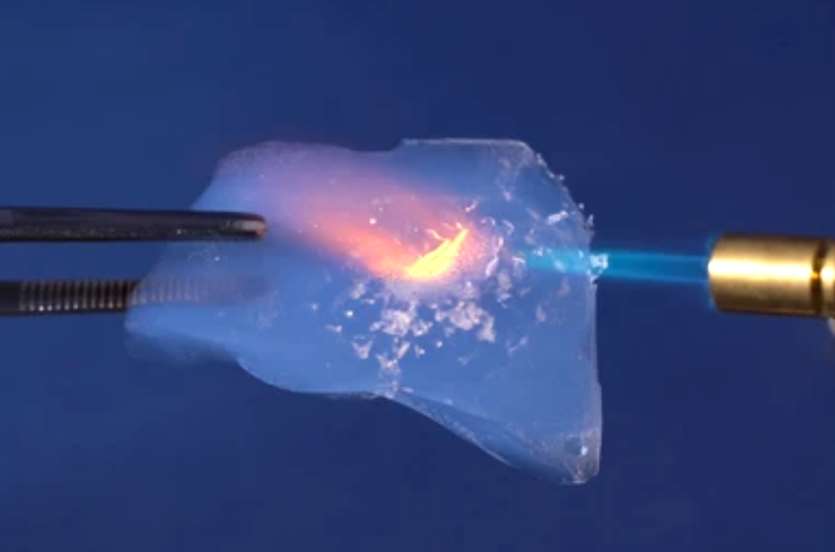

Aerogel Materials: Fireproof and Thermal Insulation Applications

Aerogels are transforming into disruptive technologies with endless industrial applications due to nanostructures, outstanding thermal insulation, and fire retardancy. They have very low thermal conductivity, are lightweight, and are highly resistant to high temperatures - which make them indispensable in construction, aerospace, automotive, and energy storage applications. In this post, we will discuss how, why, and what can be done with aerogels for fireproofing and thermal insulation.

Mechanisms of Aerogel's Thermal Insulation and Fire Resistance

It's because the nanoporous structure and material composition are what give aerogels their extraordinary properties - together they reduce heat by conduction, convection and radiation.

Aerogel nanopores limit free diffusion of air molecules, so convective heat transfer is prevented. Since the pore size is smaller than the mean free range of air molecules (~70 nm), the molecular motion is severely restricted, which reduces the gas-phase thermal conductivity. The complex three-dimensional network of the solid skeleton significantly increases the thermal path length, further reducing the heat transfer through the material.

Aerogels are porous and porous at the nano-scale absorb infrared light and thus reduce radiative heat transfer. In addition, aerogels are also commonly treated with ingredients called shading agents to make them even better - they block heat at particular wavelengths.

The solid matrix of an aerogel consists of materials such as silica or polymers, which inherently have low thermal conductivity. The extended and tortuous path of heat conduction through the solid phase increases the thermal resistance. Aerogels made of silica and polyimide in particular have high thermal stability even at high temperatures. Silica aerogels can withstand temperatures of more than 1000°C, for instance, and zirconia aerogels up to 1300°C.

Applications of Aerogels in Fireproofing and Thermal Insulation

Aerogels have a variety of applications because they are fire and thermally insulating. These are applications that we need to get better safety, energy efficiency, and reliability in our systems.

Construction and Building Materials

Aerogel is widely used in building insulation due to its low thermal conductivity and fire resistance. Aerogels are incorporated into building walls, roofs and windows to provide ultra-thin but highly effective insulation. In steel structures and concrete reinforcement, aerogel-based coatings can significantly increase fire resistance ratings, thereby enhancing fire performance. These coatings act as high temperature barriers and provide critical time for evacuation in the event of a fire.

Industrial Applications

In industrial applications, for instance, a pipe or other industrial device is sealed with aerogels, especially where extreme temperatures are a concern. Aerogel-covered cables provide strength and resist fire transmission in tunnels and data centers.

Energy Storage Systems

Aerogel materials are thermal shields in electric vehicles (EVs) to avoid the thermal runaway of Li-ion batteries. They are light and thin to make the most use of space and have strong fire resistance. Aerogels effectively isolate individual cells, slowing down heat propagation and increasing battery safety.

Aerospace

Aerogels are critical in aerospace engineering, where their low density and high thermal resistance are essential. It is integrated into the heat shields of spacecraft and re-entry vehicles to protect against extreme aerodynamic heating. On-board avionics and electronic systems are insulated with aerogel layers to ensure proper functioning under varying thermal conditions.

Aerogel Application Case Studies

| Aerogel Application Case Studies |

| Application | Aerogel Material | Purpose |

| Spacecraft Thermal Insulation | Silica Aerogels | Protect sensitive electronics from extreme temperatures. |

| Rocket Fuel Line Insulation | Nanostructured Aerogel Blankets | Minimize heat loss in cryogenic systems. |

| Space Dust Collection | Aerogel Composites | Capture high-velocity particles in space missions. |

| Entry Thermal Protection Systems | Phenolic-Impregnated Carbon Aerogels (PICA) | Shield spacecraft from re-entry heat. |

Automotive Industry

Aerogel in vehicles is deployed for insulation in the engine room and as fire protection in the interior of the vehicle. Aerogel decreases the weight of the vehicle, fuel consumption, and emissions without compromising on safety.

Future Prospects and Challenges

Aerogels undoubtedly have potential, but they are still not inexpensive to manufacture or scale. Current research aims to enhance mechanical properties, reduce manufacturing costs, and scale up the use of new technologies. Innovations like better hybrid aerogels and synthesis processes that are eco-friendly will propel aerogels into sustainable applications.

Conclusion

Aerogels represent a paradigm shift in fire protection and thermal insulation technologies. Their unique combination of nanostructural properties, high heat resistance, and fire protection capabilities address key safety and energy efficiency challenges across multiple industries. As aerogel technologies continue to advance, their role in modern engineering and design will become increasingly critical, setting new standards for material performance.

Related Hot Products from Alfa Chemistry

Please kindly note that our products and services are for research use only.